|

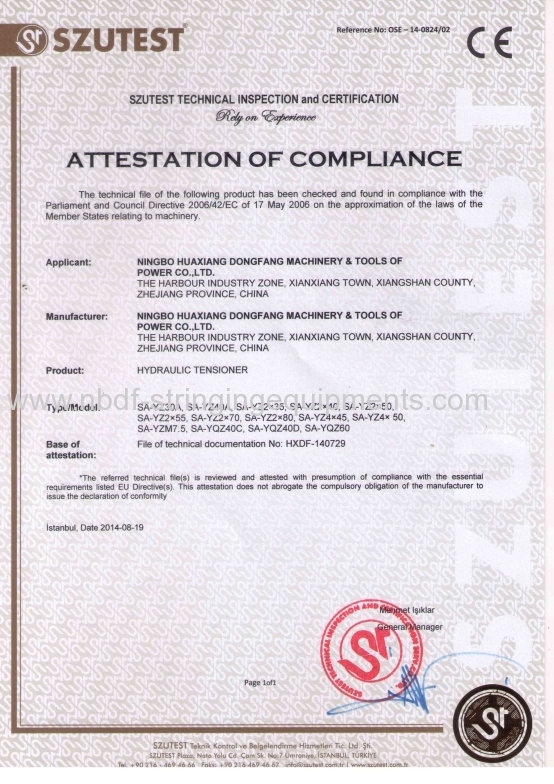

Ningbo Huaxiang Dongfang Machinery and Tools of Power CO., Ltd.

China Two Bundled Conductors Aerial Stringing Equipment of 7 Ton Tensioner manufacturer |

Two Bundled Conductors Aerial Stringing Equipment of 7 Ton Tensioner

| Price: | 120000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Two Conductors Stringing Equipment is used for overhead two conductors or OPGW stringing. We supply full set of puller, tensioner, stringing blocks.

Two Conductors Stringing Equipments are used for overhead transmission line two conductors or OPGW stringing. We supply full set of hydraulic puller,hydraulic tensioner, stringing blocks, anti twisting pilot wire rope, running boards, come along clamps, ratchet chain hoists, motorised winches, gin poles, hydraulic compressors, swivel joints, socket pulling grips, fixed joints, joint protectors, etc.

1. SA-YQ60 Hydraulic Cable Puller

Item No. | 07031 |

Model | SA-YQ60 |

Stringing capacity | 1 PILOT WIRE ROPE |

Max. Pulling Force (KN) | 60 |

Continuous Max. Pulling Force (KN) | 50 |

Speed at Max. continuous pull: | 2.5km/h |

Max. Pulling Speed (m/min) | 5km/h |

Root Diameter of Bull wheel (mm) | Φ460 |

Number of grooves | 7 |

Max. Steel rope Diameter (mm) | Φ18 |

Model of Diesel Engine | Water cooled diesel engine |

Power of Diesel Engine | 77 KW |

Rotate Speed of Engine (rpm) | 2800 |

Electrical System | DC24V |

Weight (kg) | 3000 |

Dimension (m) | 3.8 x 2.1 x 2.3 |

Application: The hydraulic puller is used to pull pilot wire rope for overhead transmission line Stringing. It is equipped with diesel engine and closed hydraulic system, it can be easily used and maintained

Features:

-With closed hydraulic circuit and variable displacement plunger pump, the pulling force could be step less controlled, and can be read on the line pull gauge.

-The max pulling force for stringing operation can be preset.

-Automatic over pulling protection system

-With the radiator imported from Germany, the machine has good heat dissipate performance.

-With a negative spring applied hydraulic released brake, and automatic overload protection.

-With hydraulic oil cooling system.

-Heat treated wear-proof steel bull wheels

-With rigid axle for towing at high speed, the machine looks beautiful.

-Integral self-loading reel winder with automatic level wind.

-Heavy duty R-tires with excellent shock-absorbing performance.

Main Components:

-Engine: Cummins water-cooled diesel engine (China)

-Main variable displacement hydraulic pump and main motor: Rexroth (Germany)

-Reducer: R.R. (Italian)

- Main hydraulic valve: Rexroth (BOSCH)

-Hydraulic instruments: WIKA (German)

-Radiator: AKG (German)

- The hydraulic reel winder is equipped with 1400mm diameter steel drum (GSP1400)

1. SA-YQ90D Hydraulic Puller

Item No. | 07042 |

Model | SA-YQ90D |

Stringing capacity | 1 pilot steel wire rope |

Max. Pulling Force (KN) | 90 |

Max. Continuous Pulling Force (KN) | 80 |

Speed at Max. continuous pull: | 2.5km/h |

Max. Pulling Speed (m/min) | 5km/h |

Root Diameter of Bull wheel (mm) | Φ520 |

Number of grooves | 7 |

Max. Steel rope Diameter (mm) | Φ21 |

Model of Diesel Engine | Water cooled diesel engine |

Power of Diesel Engine | 121 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical System | DC24V |

Weight (kg) | 4300 |

Dimension (m) | 4.3 x 2.1 x 2.5 |

Application: The hydraulic puller is used to pull four bundled conductors or 2 bundled conductors for power line construction. It is fully hydraulic controlled, easily used and maintained

Features:

- Closed hydraulic circuit,infinitely variable speed control in both rotating directions.

- The max pulling force for stringing operation can be preset, pulling force in the rope can be read on the line pull gauge.

- Automatic over pulling protection system

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure safety.

- Hydraulic oil cooling system.

- Heat treated wear-proof bull wheels

- With rigid axle for towing at high speed, the machine looks beautiful.

- Hydraulic actuated pulling rope clamp for convenient reel change.

- Integral self-loading reel winder with automatic level wind.

Main Components:

- Engine: Cummins water-cooled diesel engine.

- Main variable displacement hydraulic pump and main motor: Rexroth (German)

- Reducer: Rexroth. (Germany)

- Reel winder motor: Danfoss (Danish)

- Main hydraulic valves: Rexroth (Germany

- Hydraulic instruments: WIKA (German)

- Radiator: AKG (German)

- The hydraulic reel winder is equipped with 1400mm diameter steel drum (GSP1400)

2. 7 Ton Hydraulic Tensioner SA-YZ2X35 for 2 bundled conductors

Item No. | 07181 |

Model | SA-YZ 2X35 |

Max. Tension Force (KN) | 2X35 or 1X70 |

Continuous Tension Force (KN) | 2X30 or 1X60 |

Max. Stringing Speed(km/h) | 5 |

Max. Pullback force (KN) | 2X30 or 1X60 |

Max. Pullback speed (km/h) | 2 X 1.2 |

Diameter of wheel (mm) | Φ1200 |

Number of grooves | 2X5 |

Max. Conductor Diameter (mm) | Φ32 |

Model of Engine | CUMMINS WATER COOLED |

Power of Engine | 38 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical system: | DC24V |

Weight (kg) | 4000 |

Dimension (m) | 4.10 x 2.10 x 2.60 |

Application: It is suitable to string two bundled conductors or single conductor in overhead transmission line.

Features:

- Closed hydraulic circuit, infinitely variable tension force control in both directions.

- The max. tension/pull back force for conductor stringing operation can be presetted, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Hydraulic oil cooling system

- Bull wheels lined with wear proof MC nylon lining segments

- With 2 hydraulic power outlets to control 2 sets of hydraulic reel stands.

- Hydraulic front jack

- Mounted on trailer with rigid axle for towing at max. speed of 15 km/h

Main components:

- Engine: Cummins water-cooled diesel engine

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA

- Quick couplings: EMB

- Radiator: AKG

Shipment

1. The machine will be shipped in container

2. We will ship the products within one month normally after receiving the payment.

3. Stock is available for standard product.

Package

1. The machine will be loaded in container and fixed with steel wire rope.

2. The accessory and operation manual will be packed in plywood case.

Payment

1. We accept T/T and L/C.

2. Please send swift copy of T/T if you arrange payment by T/T

3. Please send us the L/C draft to us before issue L/C.

Why choose us:

1. High quality and competitive price

2. Leading and biggest manufacture for stringing equipment in China.

3. 25 years of production experience and more than 1000 customers in the country and abroad market. The set of 9 ton puller and 7 ton tensioner have been sold to more than 20 countries.

4. Big stock condition for fast shipment.

5. Detailed pre-sales service and fast active after-sales service. Response within 12 hours after-sales service

Related Search

Find more related products in following catalogs on Hisupplier.com

Other products from this supplier

-

3 Ton Cable Tension Stringing Equipment for single conductor OPGWSA-YQ30 SA-YZ30A

-

40 KN Cable Tension Stringing Equipments with Cummins engineSA-YQ40 SA-YQ60 SA-YZ40A

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

80 KN Cable Tension Stringing Equipments with Germany Deutz engineSA-YQ90D SA-YZ2X40B

-

9 Ton Hydraulic Conductor Pulling Machine for 18MM Anti Twist RopeSA-YQ90 SA-YQ90D